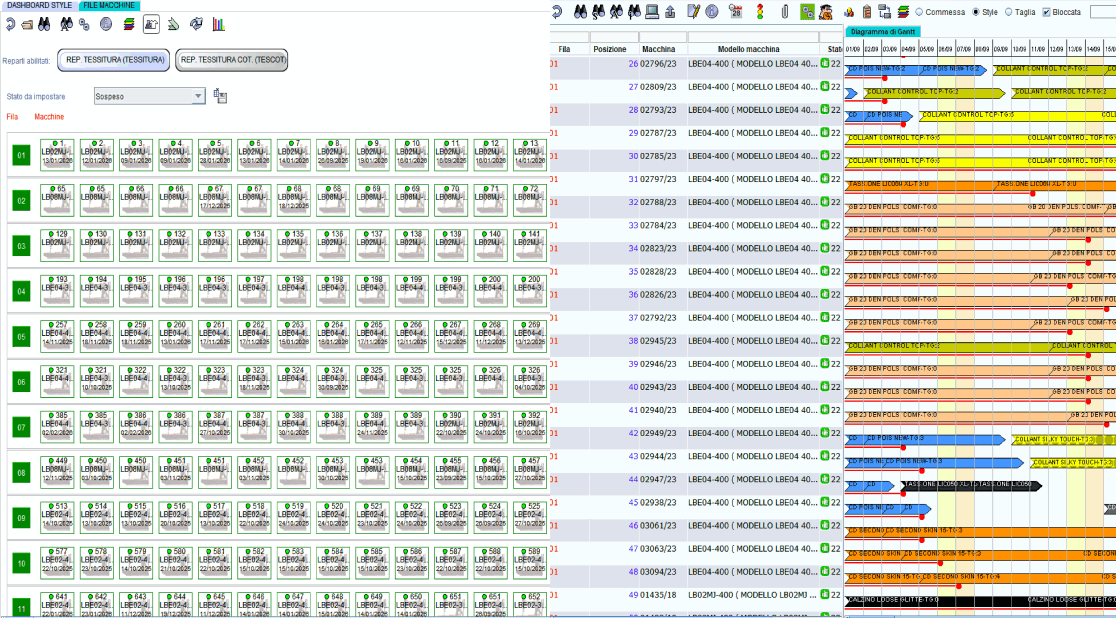

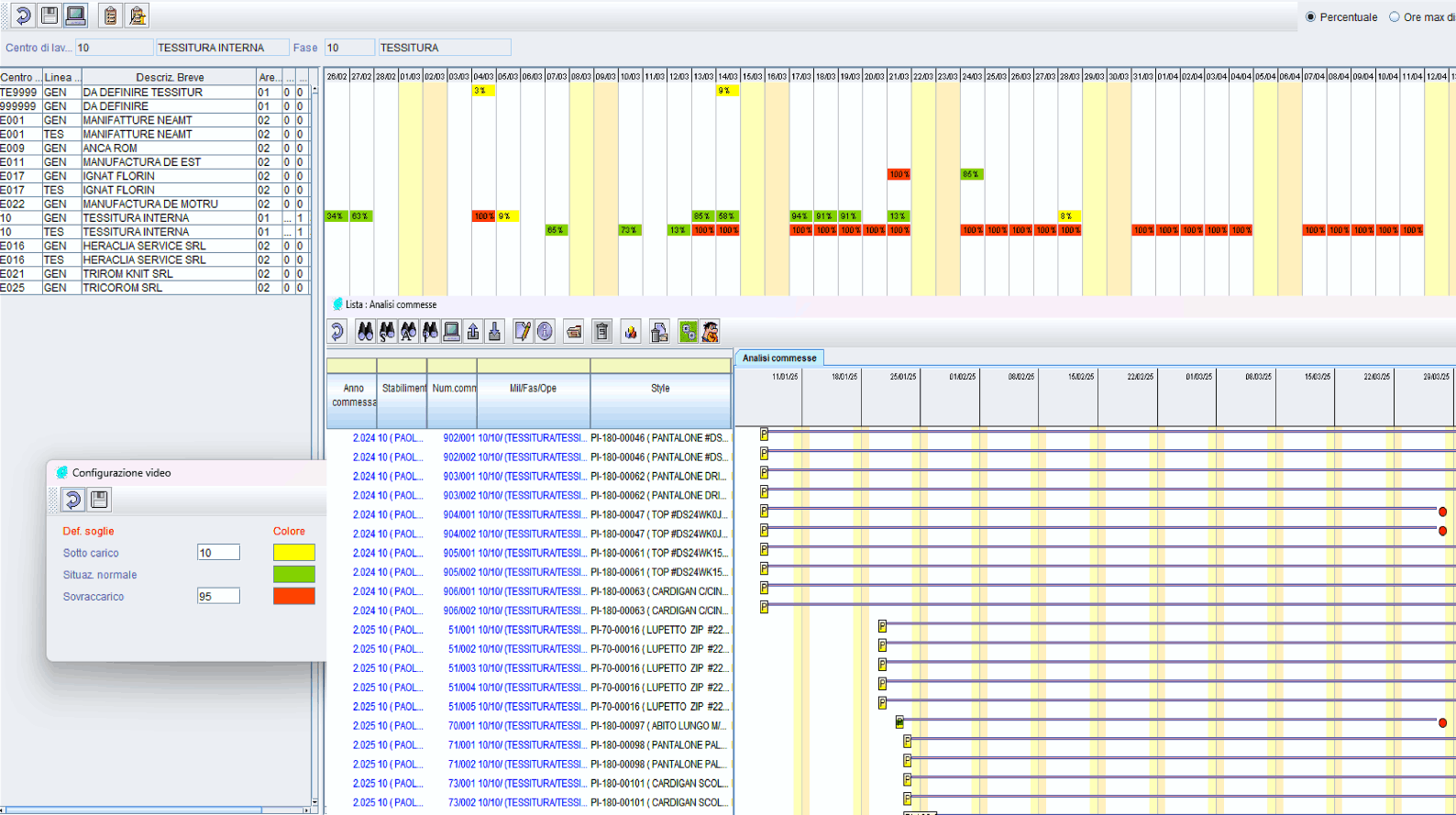

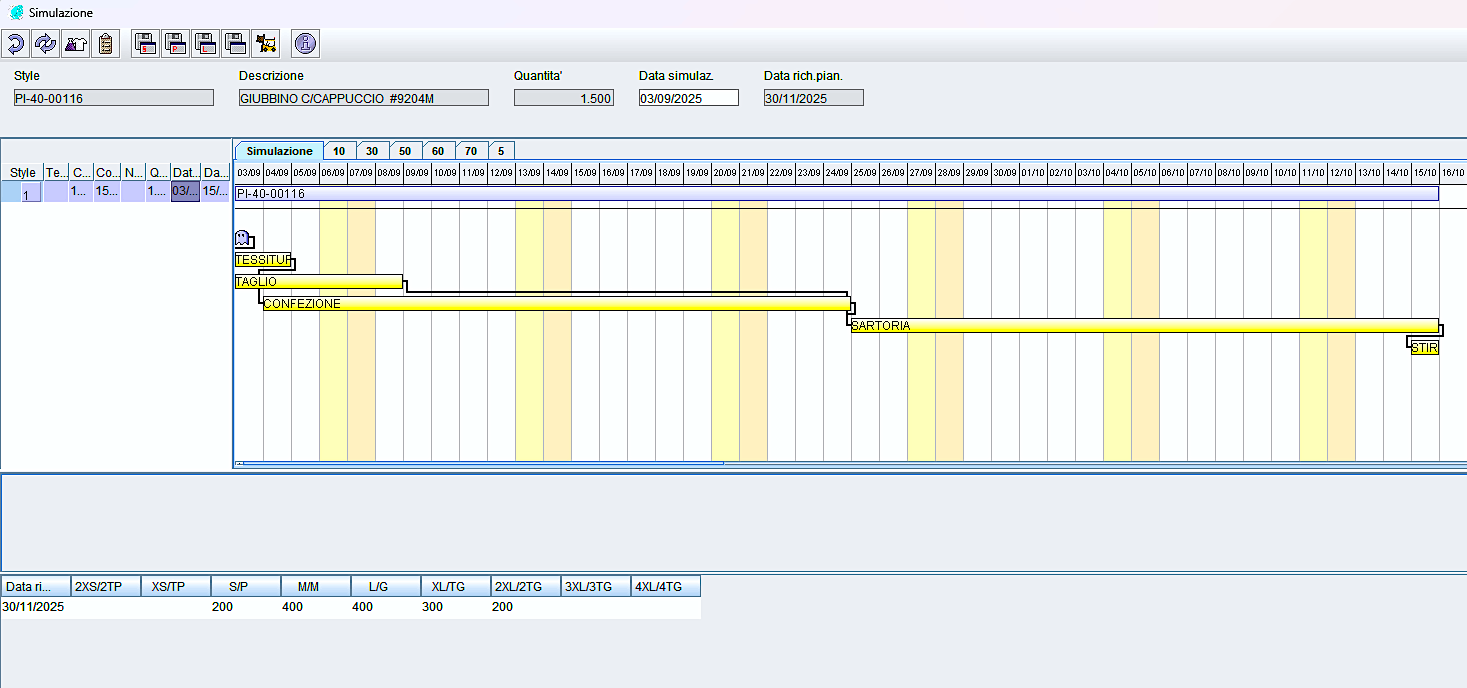

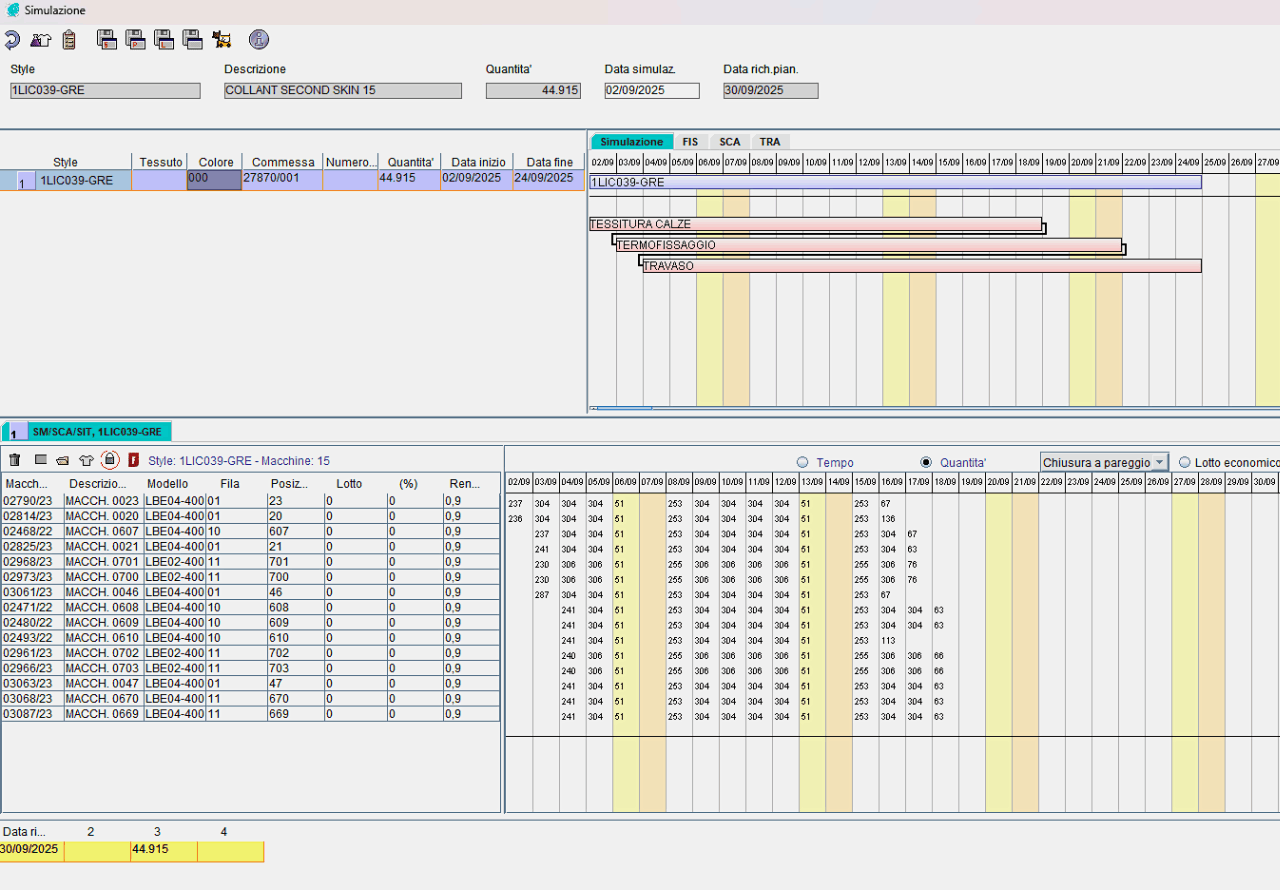

AMACHINE WORKLOAD ANALYSIS

-Style.. allows the analysis of loads for each single machine, manages the critical issues of overloads, set-up times, etc..

-Style.. allows you to manage loads and machine availability through capacity calendars, thus distinguishing any possible delay that can be foreseen first in the simulation phase and then in the production phase.

-Style.. allows the management of machine models and individual machines in iteration with the availability and ability of the mechanics to equip the machines; Style Labo, through the module that examines the availability of mechanics at finite capacity, allows you to predict machine numbers that can be used on a daily basis differently if you launch items on already equipped machines or on machines to be equipped.

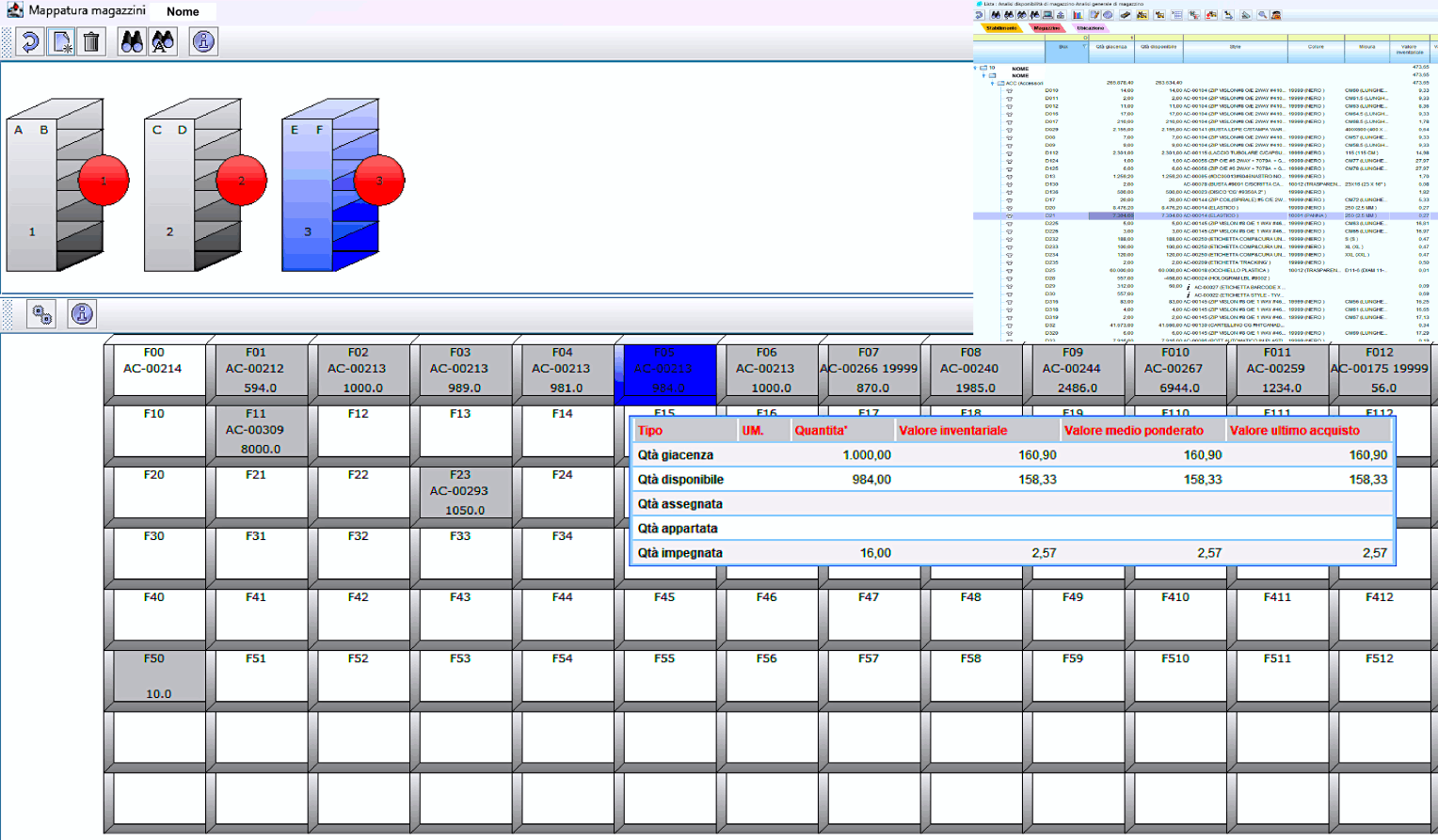

BOX MANAGEMENT

-Style.. allows punctual management of the transports between different department thanks to a scheduled transport plan; this tools will enable to monitor and consider all transport time between one production cycle and another. The transport module organises the shipment by road, sea etc..

-Style.. manages the warehouses in different departments, the divisions inside each warehouse allow the monitoring of different changes that the products may have.

-Style.. enables the mapping of the warehouses, this is also called Client Box or Technical Box. The mapping makes possible to trace the goods inside the Box and guide the way (manual or automatic) before issuing the packing list.