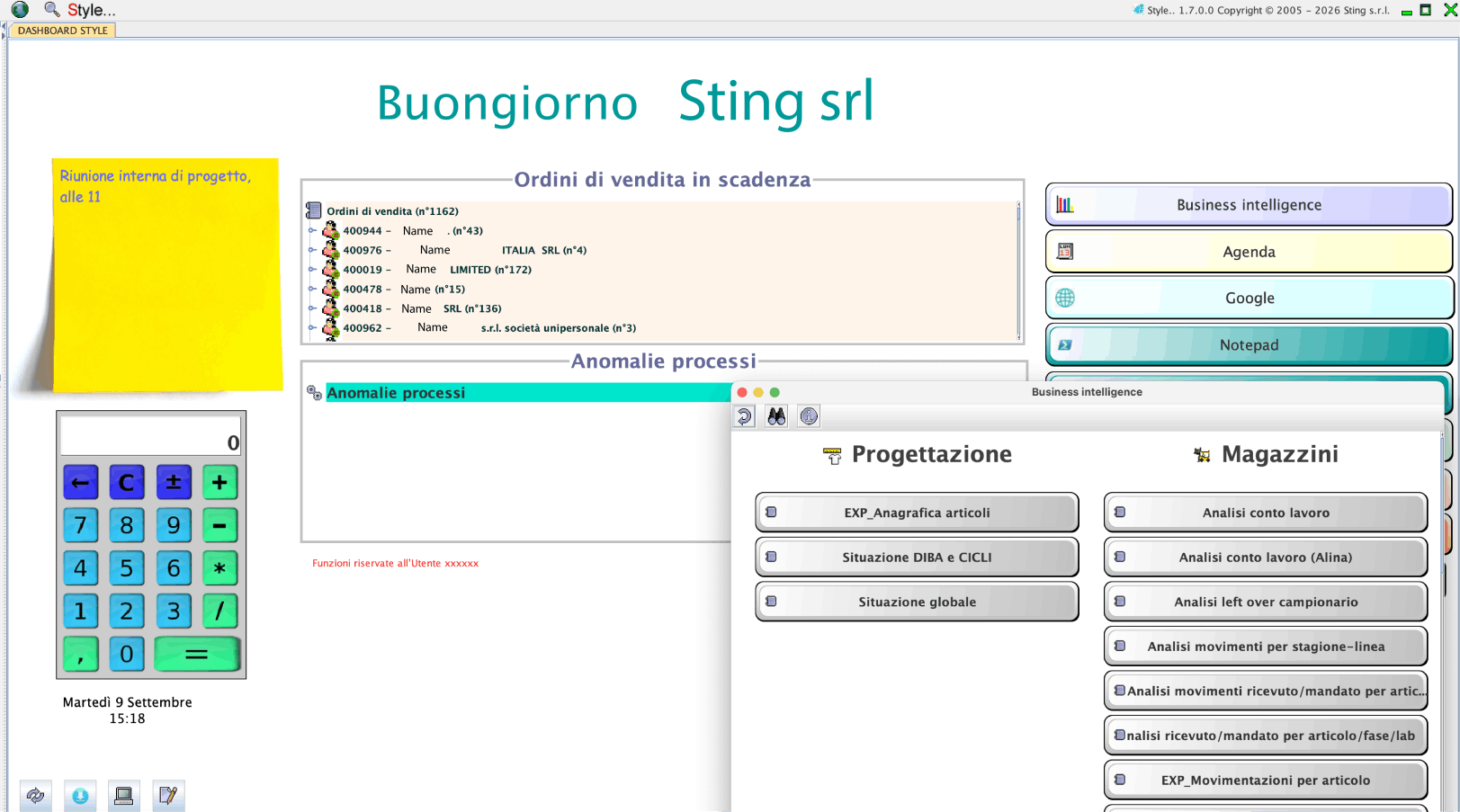

BUSINESS INTELLIGENCE

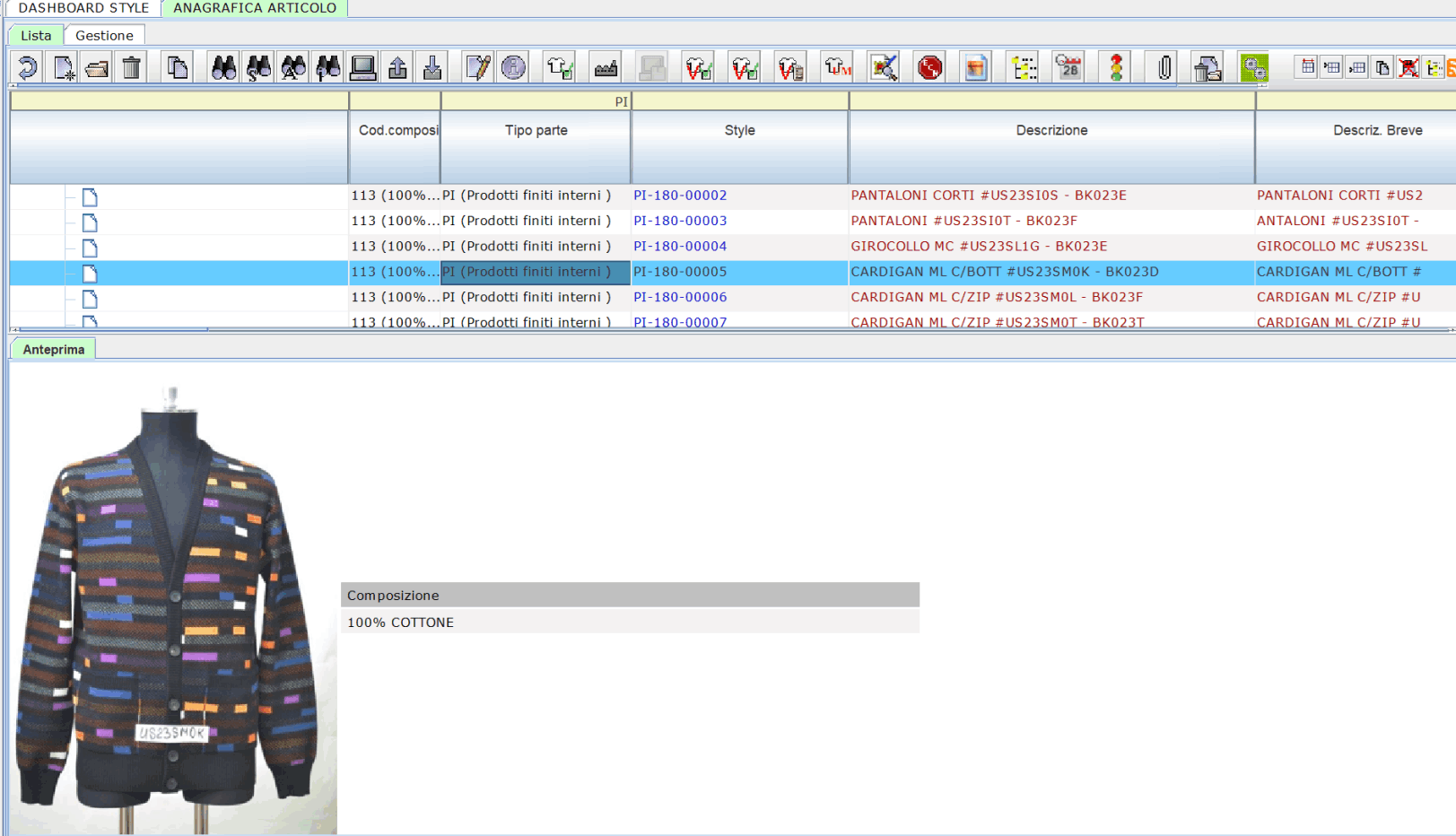

- Style.. manages the pattern-making process by using the model as the starting element of the product code, extended into its sales form. It is in the model master data that the sketch is linked to the design phase, defining the admissibility of colors and compositions.

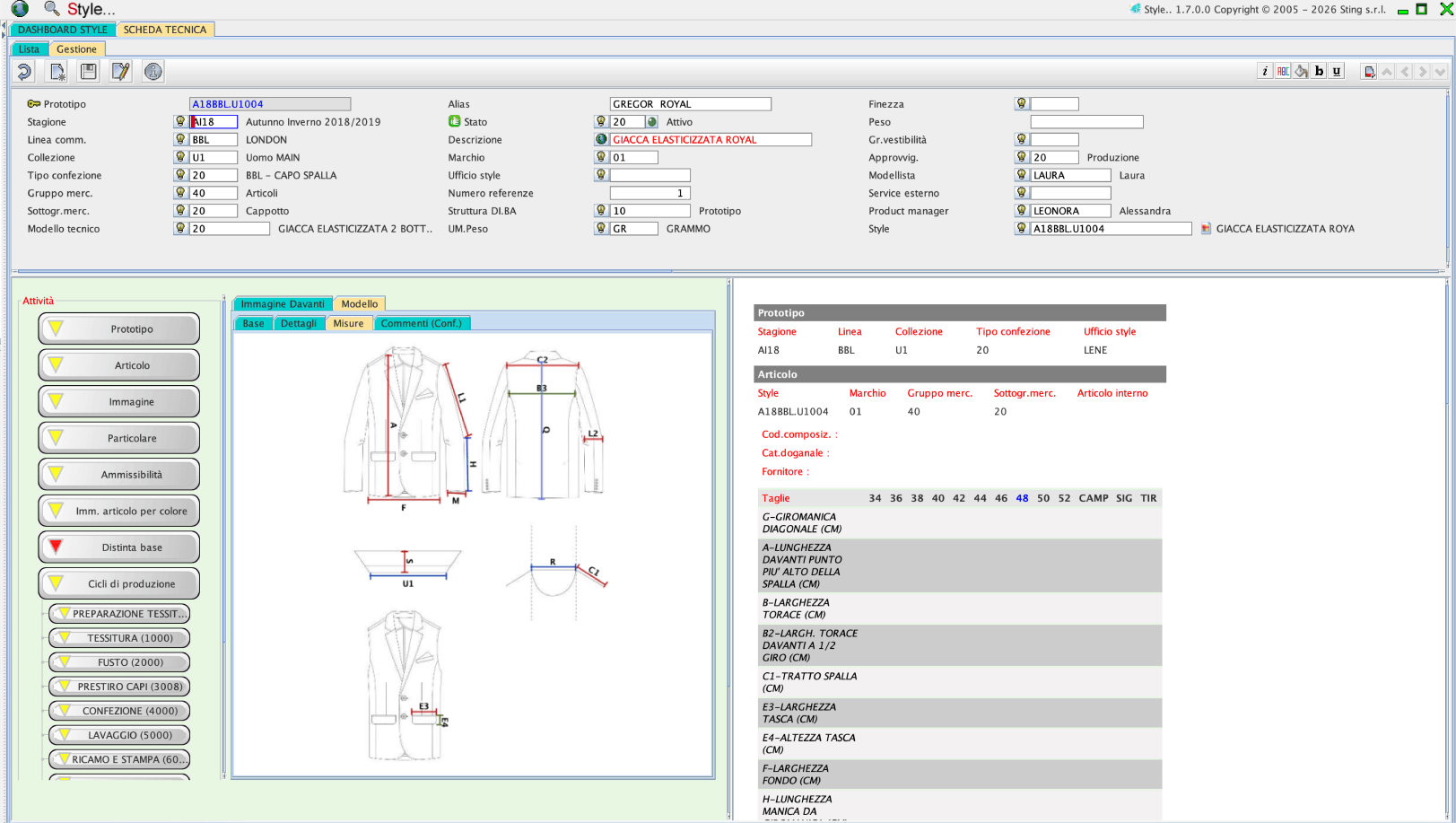

- Style.. allows any variation in the sketch: dimensions (measurements) can be modified, details can be added within the sketch, and, starting from a basic sketch (garment type), all the desired model variants can be generated.

- Style.. enables the management of garment areas as variables of a product. Zooming in on a garment area, applying the desired variant, and dimensioning the new insertion becomes a simple and rational operation; ease of execution is one of the key aspects in the design process with Style..

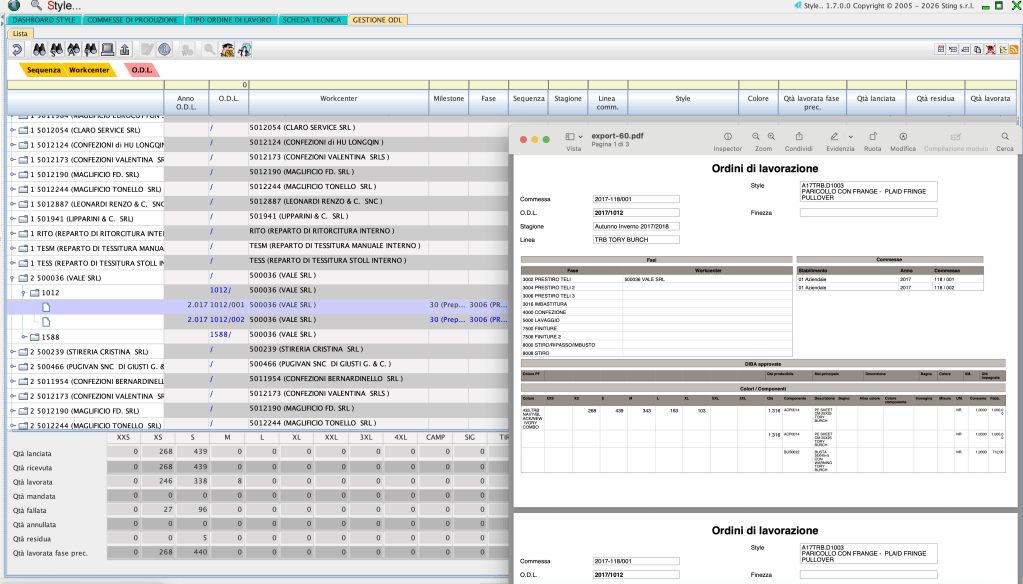

WORKING CYCLE

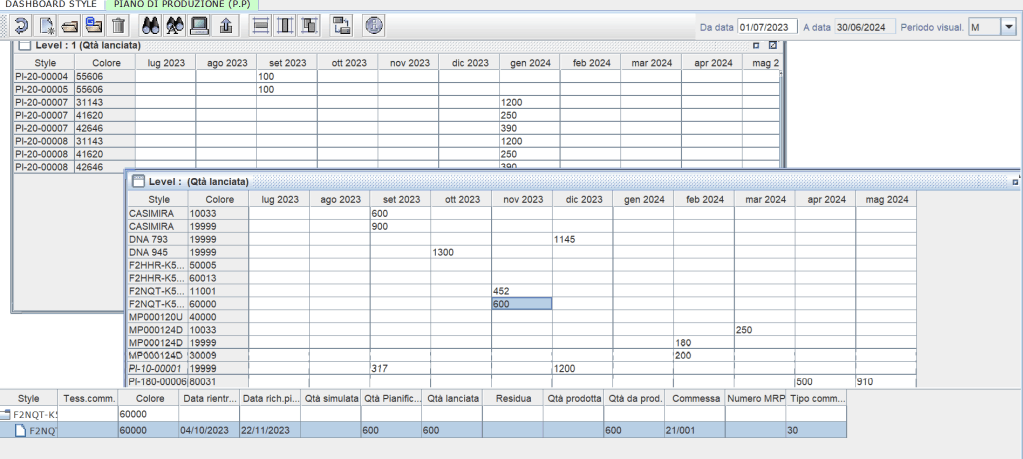

- Style.. manages collection presentations according to seasonality and commercial lines. Collections allow items to be enabled for color charts (catalogs) and to use collection price lists in different markets with their respective currencies.

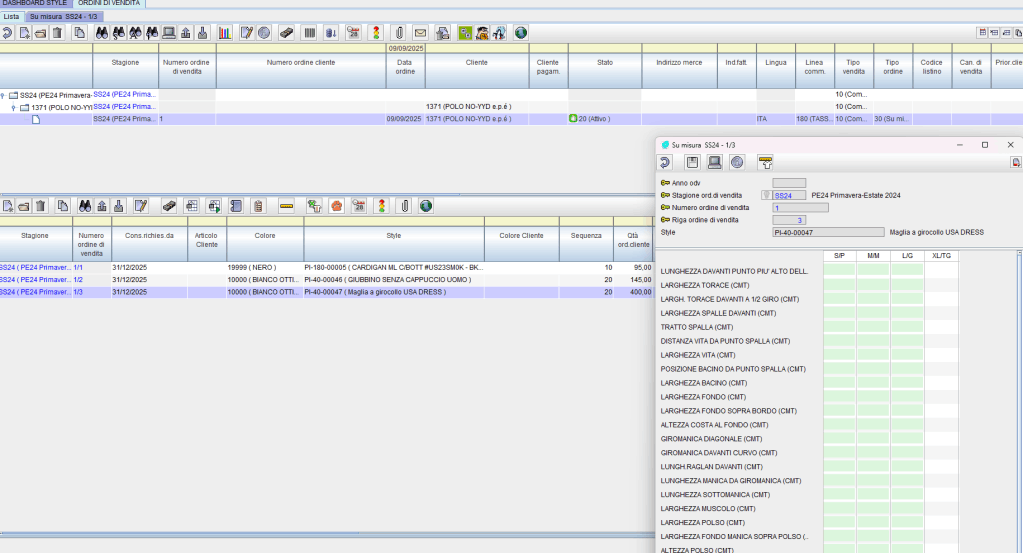

- Style.. manages sales with the same operating methods, both internally within the company (sales representatives) and through B2B (agents, stores, trade fair stands, etc.), eliminating the need to use alternative sales collection tools such as traditional agent systems, store systems, or immediate stock sales.

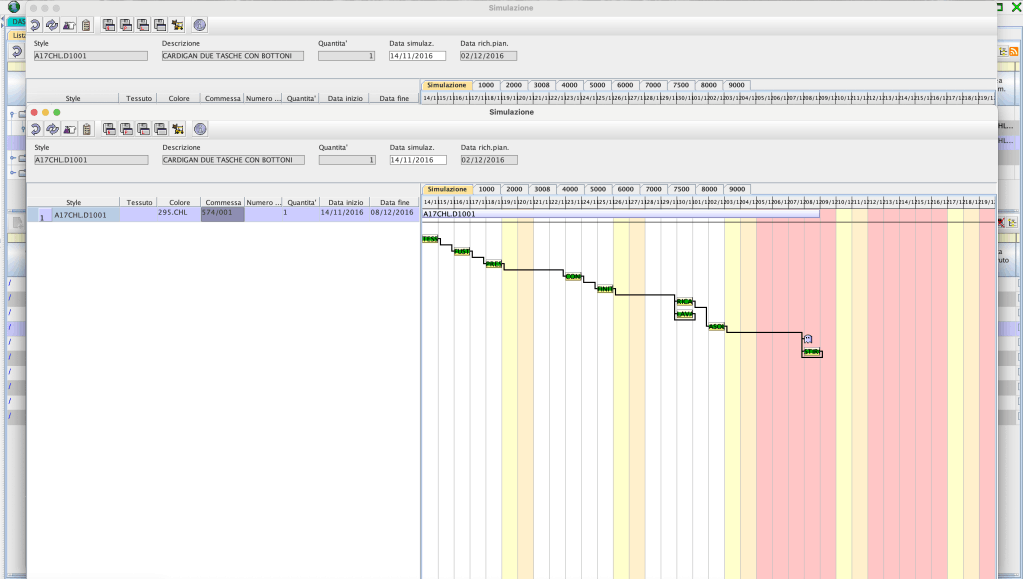

- Style.. enables balancing and online suggestions of missing products and predictable deliveries (A.T.P.) already at the sales order stage. It also allows, as an option, the assignment of production by customer or by warehouse (Strong or Light), enabling online monitoring of deliveries for each individual sales order line.

- Style.. supports the management of made-to-measure orders. Already at the order acceptance stage, it is possible to enter the measurement points of the individual concerned, ensuring precise customization management.