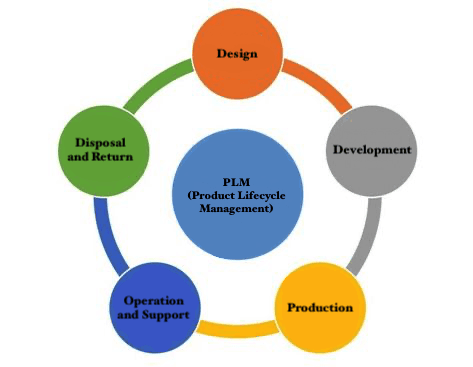

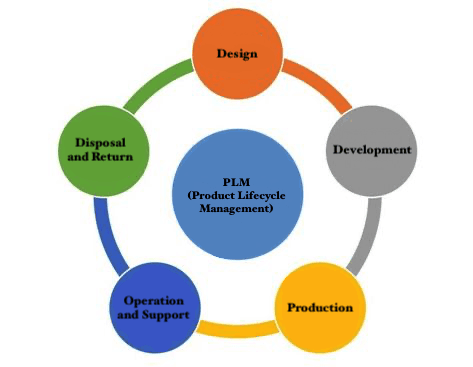

Product Lifecycle Management (PLM) is a highly advantageous strategic process that manages the entire product journey, from creation and design to development and delivery. It is a management platform that integrates all elements and data to ensure a holistic view of the physical and digital information of a product.

PLM is the result of faster innovation, empowerment, and perfected product. PLM "manages" both direct and indirect costs existing during the design, production, development, and sales phases of the product. The comprehensive product view allows the enhancement of practices and methodologies that have consistently yielded better results over time in companies.