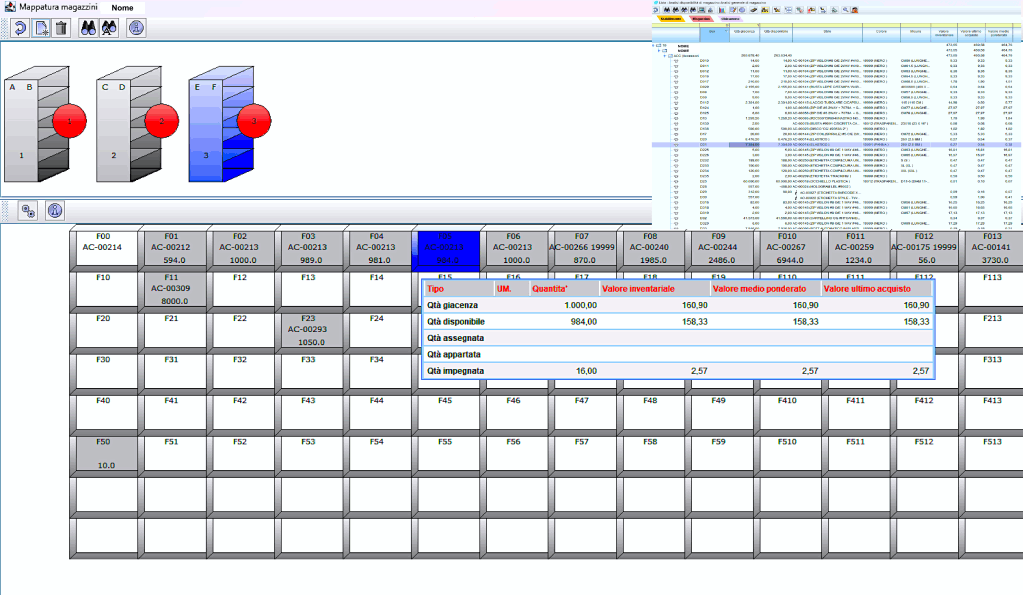

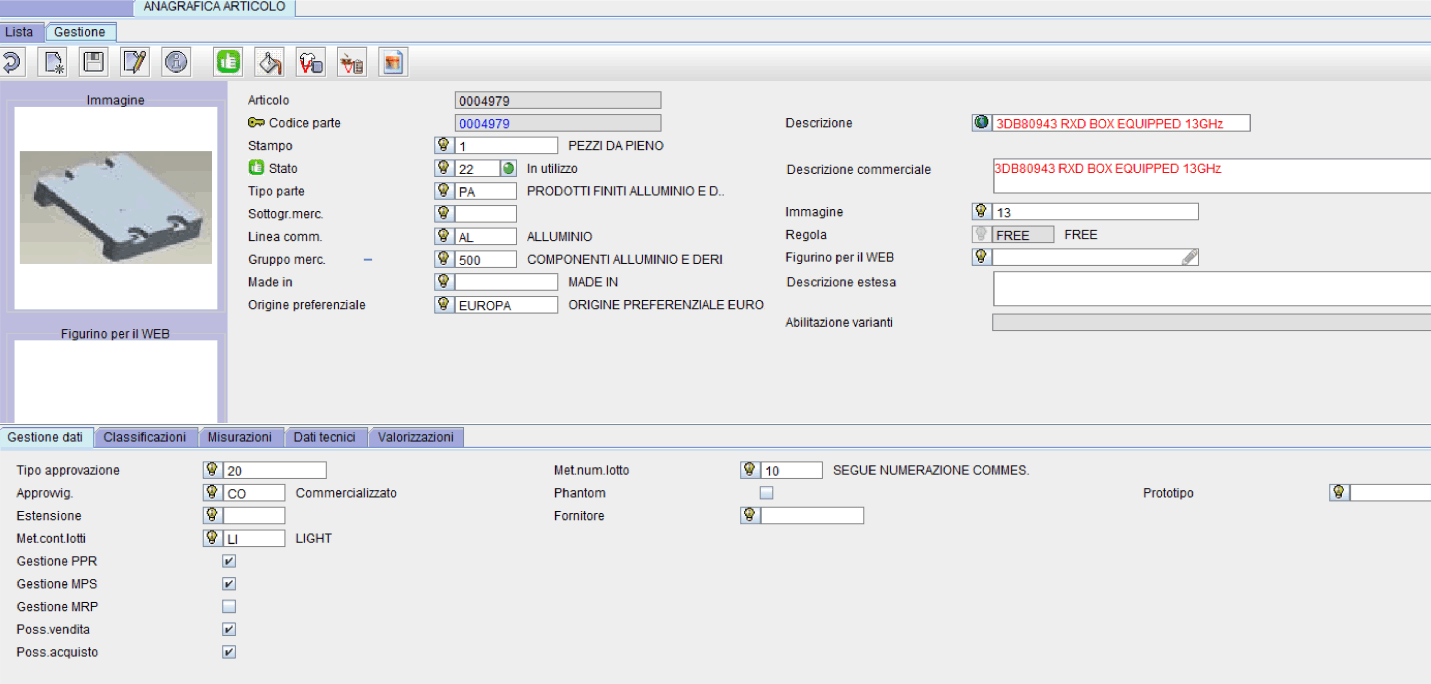

ARTICLE MASTER DATA

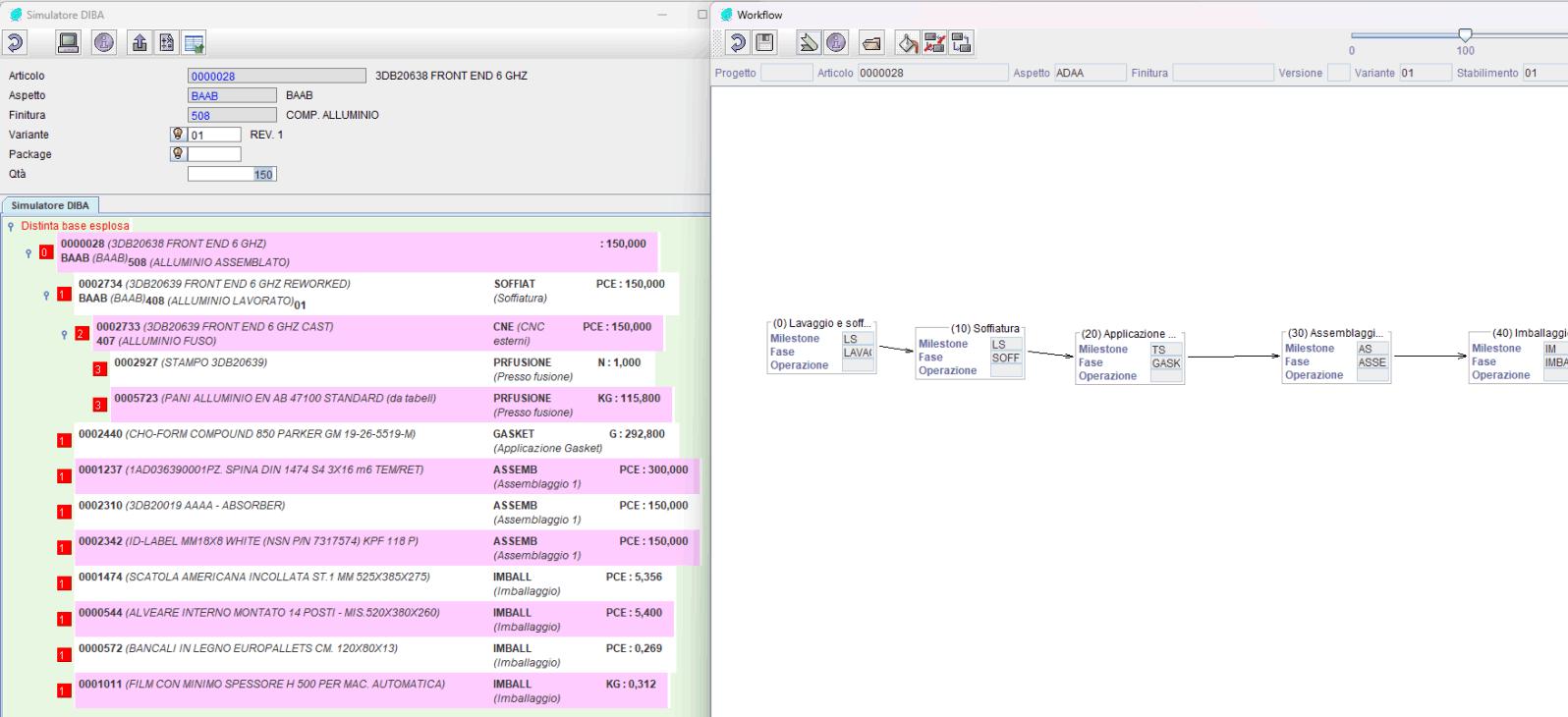

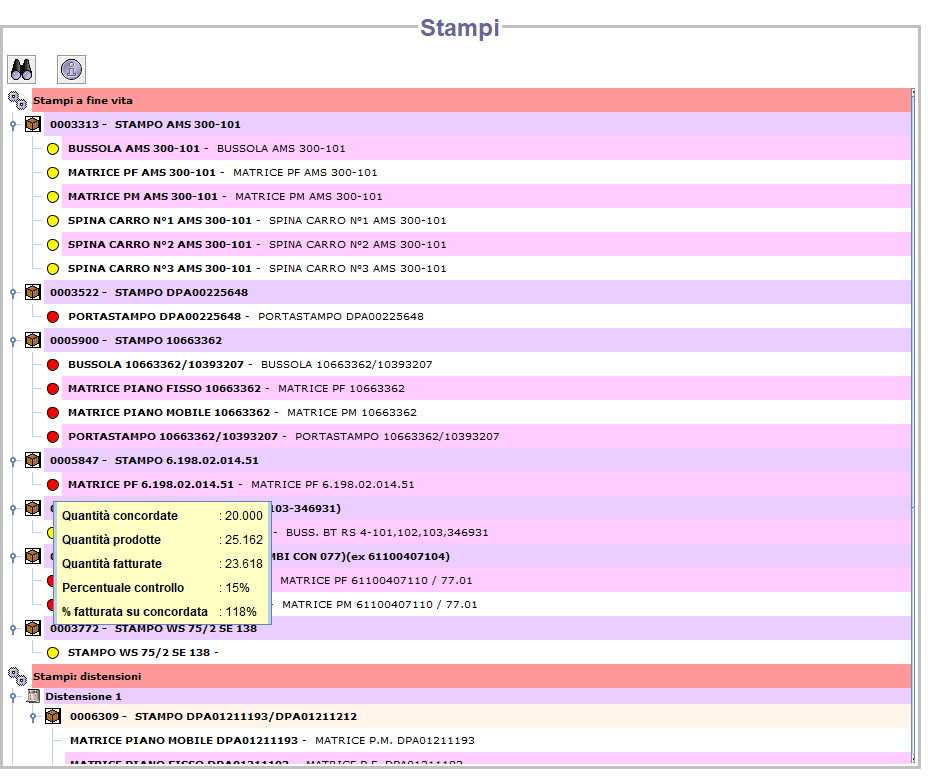

- Style.. manages the mold directly within the article master data. In the mold master data, it is possible to associate an image with the design phase, defining the admissibility of the item in relation to finishes, compositions, or variants.

- Style.. allows any variation of the finished product: measurements can be modified, and details can be added within the technical drawing starting from a base image.

- Style.. enables managing details as product variables. Enlarging an area of the parts, applying the desired variant, and dimensioning the new insertion becomes a simple and rational operation.

- Style.. simplifies operations and supports the study and design of the mold.

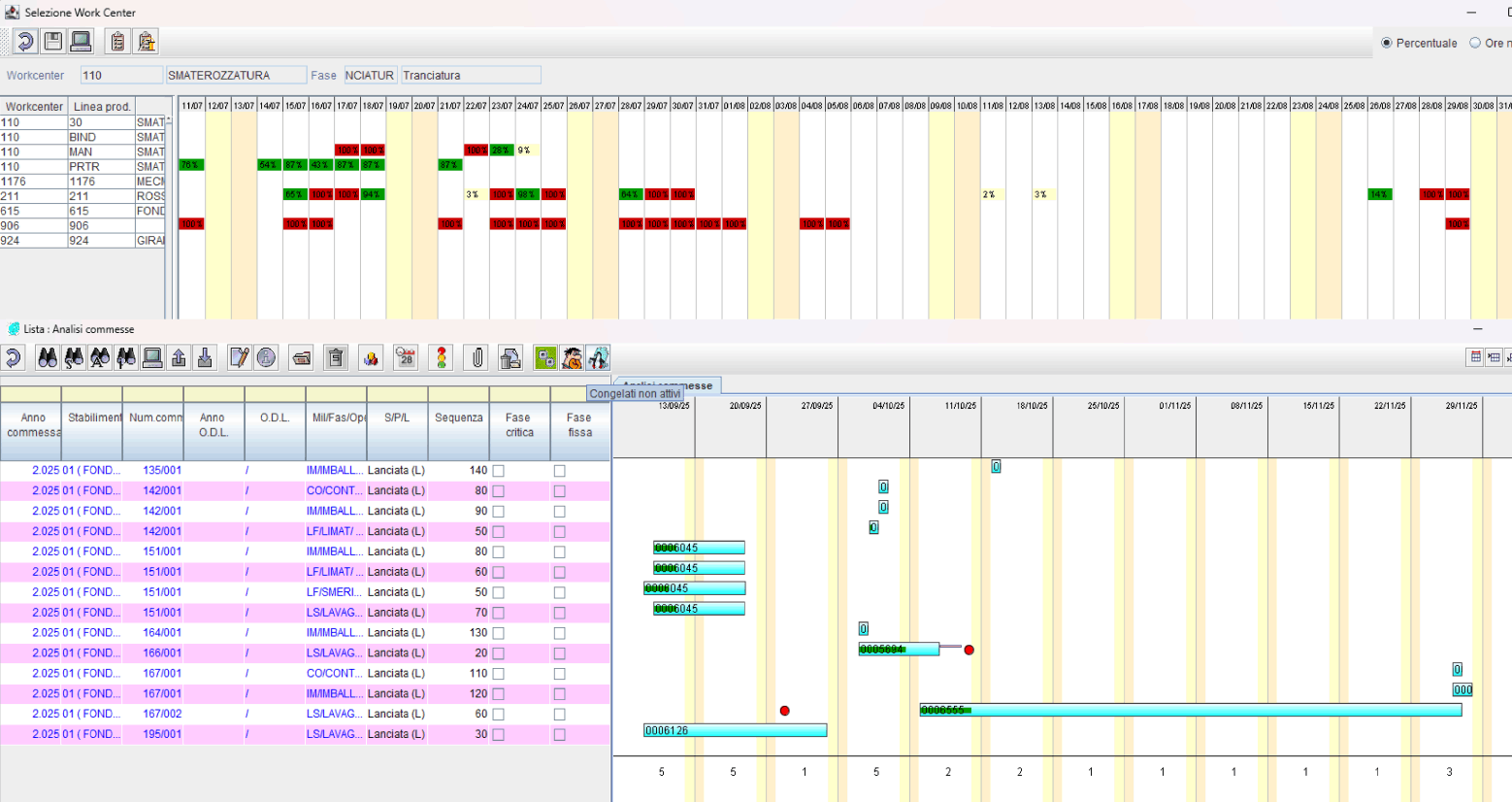

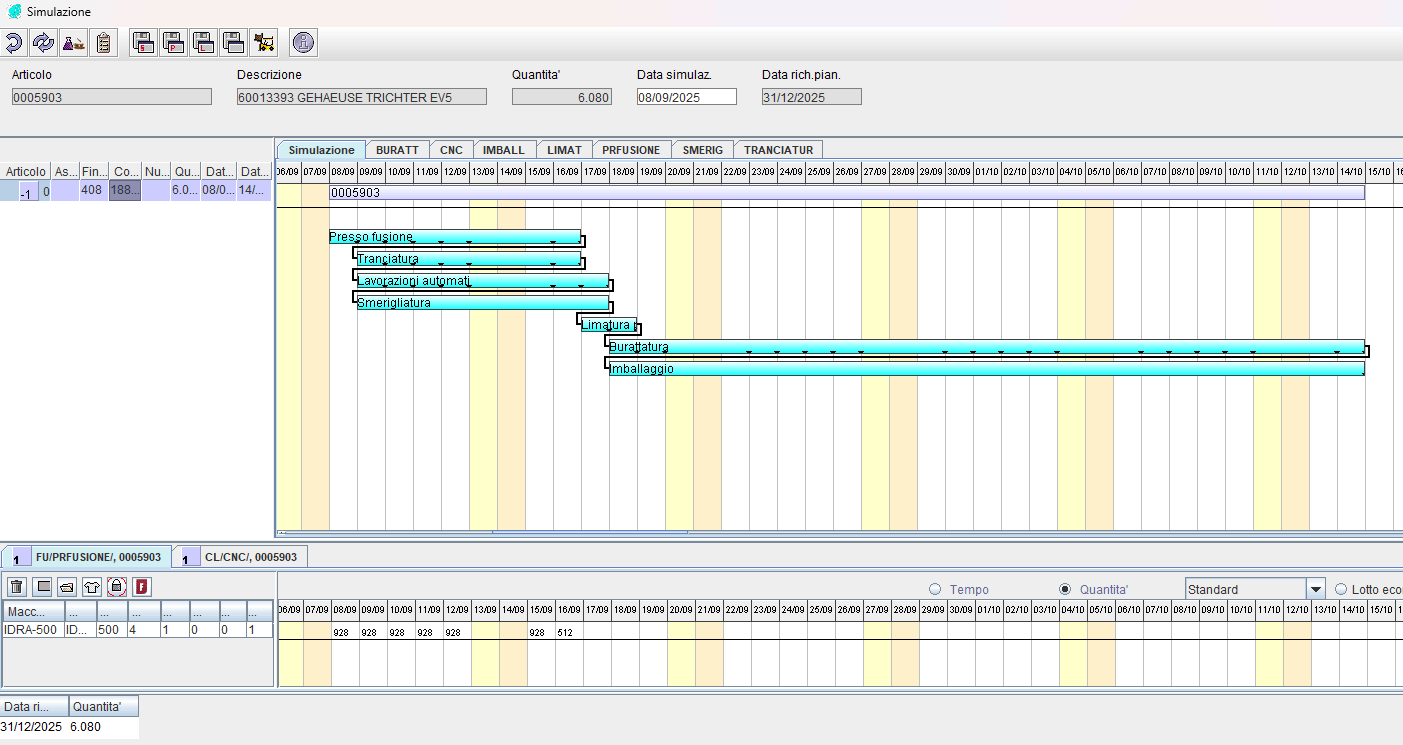

WORKING CYCLE

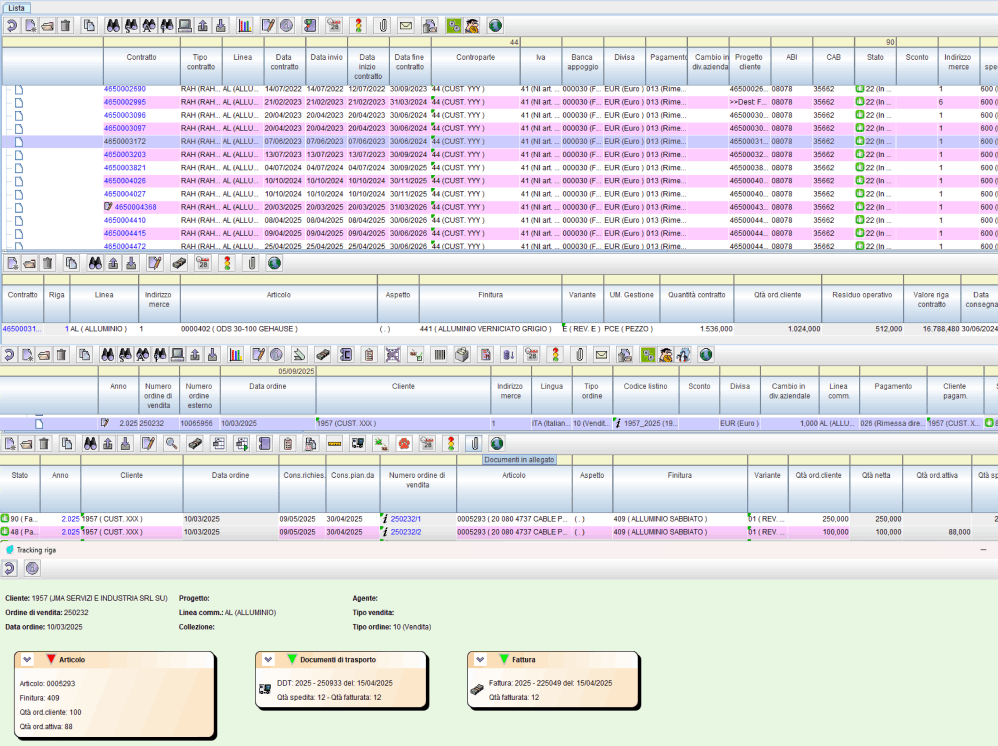

- Style.. manages contracts for continuous production and negotiations related to contract presentation, organized according to customer requirements.

- Style.. manages sales using the same operational methods, both internally within the company and through mobile functions.

- Style.. enables balancing and online suggestions for missing products and expected deliveries (A.T.P. – Available to Promise) already at the demand formulation stage (sales order). It also allows production assignment, optionally by customer or by warehouse (Strong or Light), monitoring online the deliveries for each individual order line.